Dr. John Abraham was recently granted Indian patent for his innovation – “A method to produce bio-diesel production from rendered chicken oil”.

In an Exclusive Interview to Poultry TRENDS magazine, Dr. John Abraham shares the process, economics, implementation options and how poultry industry can be made profitable and sustainable through biodiesel project.

Excerpt of the interview are reproduced hereunder:

What propelled you to make biodiesel from poultry waste?

This idea struck me, when I went to Namakkal Veterinary College for my Ph.D Programme. In Namakkal, there are about 1000 poultry farms with stocking capacity of 2-3 lakhs birds within a radius of 40 kilometer. The daily mortality of these farm accounts to about 60-90 birds per farm. These birds used to be brought to the Veterinary College for postmortem. Since the bio-secure disposal of these birds was a daunting task, the college established a rendering plant which could convert these waste into carcass meal and Rendered Chicken Oil (RCO). Carcass meal was used as pet feed ingredient and biofertilizer. But there was no use for RCO. My guide and co-guide urged me to find out a use for RCO. I accepted the challenge. After many days of study and trial and error experiments, I proposed that biodiesel can be made from RCO and I took up my Ph.D research on this project.

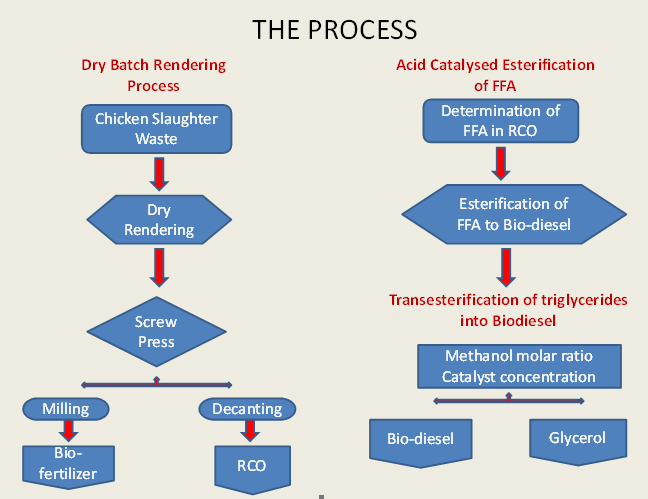

Describe the process of producing bio-diesel from chicken slaughter waste?

After collecting the broiler slaughter waste, (including feathers, viscera, shank and head) from chicken shops, the process called ‘dry rendering’ (The waste material is first dry cooked, then steam sterilized i.e. 130° C at 2 bar pressure and then moisture reduced to 10%) starts to transform it into carcass meal a valuable feed ingredient for pets and fishes. After that chicken oil a byproduct of rendering is converted to biodiesel in a two step chemical reaction called ‘acid catalysed esterification of Free Fatty Acids’ and then ‘transestericiation of tryglycerides’.

What is the economics of ‘bio-diesel production from rendered chicken oil’ project?

The collection of the raw material, itself fetches money. 1 kg slaughter waste is collected at the rate of Rs.7/kg from the chicken shops. 36% of the collected slaughter waste is converted into protein powder in the rendering process, which sells for Rs.35/kg and 10% of it is RCO. 87% of the RCO is transformed into biodiesel and 13% of RCO is crude glycerol which sells for Rs.90/kg. The production cost of biodiesel is only Rs.36 per litre. For commercial sales 12% GST is applicable.

How is the bio-diesel derived from poultry waste different from other biofuels?

Biodiesel can be prepared from any oil. The basic criterion is that the cost of the raw material should be one-third the cost of the present cost of diesel. The Indian biodiesel policy has prohibited the production of biodiesel from edible oil as it may cause scarcity and inflation. This biodiesel, since it is made from animal fat has high cetane number of 72 while the cetane number of petro-diesel is only 54. This indicates that this biodiesel has short ignition delays in engine, improving the engine efficiency. It has 11% oxygen by weight which leads to complete combustion in the engine, leading to reduced engine emission by 47.2% at 20% blending (B20). It also has lubricating properties and makes the engine smooth.

What challenges did you face in the research and patent process?

This was a new field all together (Bio-diesel researches are carried out at Agriculture Engineering Colleges or Bioenergy department of Institutes of Technology). Neither I nor my guide had any previous experiences with bio-diesel. So I had to toil a lot learning everything from the fundamentals to the research problem. The research proceeded by trial and error, each experience making an advancement and then optimizing the process parameters for maximum yield. Testing of biodiesel was carried out at the centre of excellence for biofuel of the Agriculture Engineering College of Tamil Nadu Agri University and engine testing was carried out at Palakkad Engineering College.

Regarding patent, the application was filed on 18th January 2014 and after the procedures, the patent office made the decision on 27th April 2020 that the claims are found in order for the grant, but since a biological material from India was used in the patent, they insisted that the patent certificate will be issued only after producing the agreement with National Biodiversity Authority of India for which it took more than a year and the certificate of grant was issued on 7th July 2021.

How can the poultry industry implement the bio-diesel project?

There are two ways in which this project can be implemented.

- In Kerala State, rendering plants had come up which collects the chicken slaughter wastes from chicken shops of a district, render it and produce protein powder for pet and fish feed. They can install a screw press which would extract the oil. When oil is extracted, the protein percentage goes up and they would get more money for their protein powder. This oil can be converted into bio-diesel by installing a biodiesel plant. This biodiesel can be used as a fuel for their boilers which produces steam and also for their vehicles used for collection, which would reduce their rendering cost considerably.

- In areas where there are large number of poultry farms: (like Namakkal) The poultry farmers association can put up a rendering plant and a bio-diesel plant, where the dead birds from all the farms will be collected and rendered. The protein powder can be sold and the biodiesel produced can be use in their boiler and for their vehicles.

How the poultry industry can be made profitable and sustainable through biodiesel project?

This project produces ‘Wealth from Waste’. Chicken slaughter waste which used to cause pollution and threat to human health in the wake of emerging diseases, can be transformed into three valuable products without producing further waste.

- Bio-diesel a renewable biofuel which can drastically reduce engine emissions

- Chicken carcass meal a protein feed supplements fork animal approved by FDA, and

- Glycerol, which finds variety of application in pharmaceuticals baking and industry.

The value of these products especially since the diesel price is sky rocketing can produce additional income to supplement the poultry industry for profit and sustainability.

What is the potential of this biodiesel derived from poultry waste in Indian market?

The Indian biofuel policy 2019 proposes 20% blending of diesel by 2023 for national energy security. The biodiesel required for 20% blending is 25.7 MT. This is a huge market which cannot be fulfilled by any other inedible oil sources. In this context the biodiesel derived from poultry waste has huge potential as it provides good fuel properties for the diesel engine and drastically reduces the engine emission. The goal of the biofuel policy is the reduction of import of crude oil by 10% in four years time.

Bio-diesel is not a replacement technology, it is a transition technology to help clean up our environment by keeping the manufacture and consumer as local as possible. It is not about replacing all of our petroleum imports; It is about not importing so much.

What is the environmental impact of this invention?

There are two major environmental impact of this invention.

- The unscientific and unhygienic disposal of broiler slaughter waste posing catastrophic threats to the human population and to the environment in the wake of emerging diseases like avian flu and swine flu, will be solved by the planned collection and scientific utilization of broiler slaughter waste by dry rendering process to produce carcass meal. As present, the disposal of broiler slaughter waste causes ground and surface water pollution, obnoxious odors and health hazards posed by indiscriminate breeding of pathogenic microorganism, parasites, house flies and also indiscriminate breeding of stray dogs which is spreads rabies. All these problems will be solved.

- Diesel engines are a major source of environmental pollution. Acid rain, global warming, climate change and health hazards like cancer are the ill effects of increased pollution. Recently, diesel vehicles were banned in Delhi due to rising levels of pollution. The major impact of this innovation is on all diesel vehicles. The bio-diesel produced from rendered chicken oil contains 11% oxygen by weight which burns completely inside the engines reducing the engine emissions by half. When used at 20% blending level can reduce the engine emissions by 47.2%, thus have a considerable impact on environmental pollution, mitigating climatic change. It can be confidently stated that this invention reduces the carbon foot print and earns valuable carbon credits.

Dr. John Abraham, MVSc (IVRI), Ph.D (TNVASU), presently working as Associate Professor, Dept. of L.P.M, College of Veterinary and Animal Sciences Pookode, Wayand, Kerala, India . He was awarded first rank and 4 gold medals for his Ph.D work entitled “Utilisation of Dead Poultry Birds for Biodiesel Production”. He was also recently granted Indian Patent IN 371344 (219/CHE/2014)- A method to produce bio-diesel production from rendered chicken oil. He also holds patent for “Bicycle type milking machine” and two design patents (Drinking bowl for cattle and Transformable goat pen). He has authored a book entitled ‘Swine Production and Management’ which was published by CRC Press, Francis and Taylor. He was awarded the Atal India Challenge-2019, DST-Lockheed Martin-India Innovation Growth Award-2016, Millennium Alliance National Award-2016, Dr. Verghese Kurien’ Memorial Best Scientist Award and Best Teacher Award-2013.

For any queries, Dr. John Abraham can be reached at johnabe21@gmail.com