It is imperative that poultry houses are disinfected as part of any successful disease prevention program. In recent years, the density of birds kept indoors has increased and infectious diseases are spreading.

Commercial Director,

Vamso Biotec Pvt Ltd,

Gurugram, Haryana, India

leena.bora@vamsobiotec.com

For the poultry industry, diseases are costly and difficult to control. No poultry producer would consider a disease prevention program complete without a comprehensive cleaning and disinfection plan.

The simple meaning of the term disinfection is the use of chemicals (disinfectants) to kill germs or reduce harmful microorganisms on surfaces and objects. The main objective of these disinfectants is to minimize microbial populations by acting on the microorganisms to damage their membranes, limit their metabolism, or cause cell lysis.

Ideal Disinfection starts with Cleaning

A poultry house must be meticulously cleaned by following a series of sequential steps before actual application of disinfectants. Each of these steps is important– dry cleaning, wet cleaning, low pressure washing & high pressure washing followed by drying. Nearly 80% of the disease-causing organisms will be eliminated by a thorough cleaning.

Dry Cleaning – Dust and other loose debris from ceilings, light fixtures, walls, cages or nest boxes, fans, air inlets, etc. should be swept or blown onto the floor. All feed should be removed from feeders. It is necessary to clean up accumulated dirt, filth and manure from perches and cages. There should be no rubble on the floor. The floor should be swept to remove as much debris as possible.

Wet Cleaning – Soaking, washing, and rinsing are all parts of wet cleaning. In order to remove debris and films and increase the penetration of disinfectant agents, detergents and other surfactants are frequently added to washing solutions.

Low Pressure Washing: Perches, cages, floors and other distinguishingly dirty areas require thorough soaking before being cleansed with a low pressure sprayer. The collected dirt and litter must soak until they are sufficiently softened to be easily removed. Wash every surface in the structure, paying specific attention to window sills, roof trusses, wall sills and any other area where dirt and dust could collect.

The cleaning solution could be acidic or alkaline. Acidic cleansers work well to get rid of any mineral deposits or oxidation on surfaces and are frequently used on metal surfaces. Salts, starches, carbonates, and insoluble hydroxides are all examples of compounds that are best removed with acidic cleaners. Acidic solutions can be used to clean equipment in poultry sheds that has hard water stains or mineral deposits (calcium and magnesium precipitates).

Because most soils are acidic, alkaline cleaners are effective. Alkaline cleaners get rid of organic residue including variety of soils like oils, fats and greases. For the majority of cleaning jobs in chicken houses, alkaline cleansers or blends of alkaline and acidic cleaners may be used.

High Pressure Washing: Washing with a high pressure sprayer is to ensure a thorough cleaning and removal of harmful residues. Use of a high pressure sprayer during cleaning will guarantee complete cleaning and removal of harmful residues. One of the finest techniques to guarantee a complete cleaning at this point is manual scrubbing with a brush that is relatively stiff. A high-pressure cleaner is the preferred piece of equipment for ensuring proper cleaning in chicken sheds. High Pressure washing enables:

High Pressure Washing: Washing with a high pressure sprayer is to ensure a thorough cleaning and removal of harmful residues. Use of a high pressure sprayer during cleaning will guarantee complete cleaning and removal of harmful residues. One of the finest techniques to guarantee a complete cleaning at this point is manual scrubbing with a brush that is relatively stiff. A high-pressure cleaner is the preferred piece of equipment for ensuring proper cleaning in chicken sheds. High Pressure washing enables:

- Preparation for repairs: A fantastic approach to remove old, flaking layers that could lead to issues later is by high pressure washing.

- Protection of farms from damage: High pressure washing stops the formation of mold and moss, which can be problematic if left unchecked.

- Thorough cleaning of the farm: A high pressure wash can benefit outdoor fixtures and any concrete surface.

Drying: Drying the building and all surfaces to be disinfected is crucial for proper disinfection. All windows and ventilation openings are to be kept open after washing. A blower or a fan can also be used if available. Cleaning on a dry, sunny day will make the drying process easier.

Only after Cleaning, Disinfectants are to be used

Disinfectants should be applied only after the building and equipment have been thoroughly cleaned and dried. The most popular chemical disinfection techniques in poultry buildings include fumigation, foaming, thermo-misting, and spraying. To ensure that all surfaces, pieces of equipment, and items inside the sheds are covered during disinfection, a proper protocol should be followed. We must be mindful that disinfection is not a substitute for cleaning.

Therefore, several qualities should be considered while choosing a disinfection agent, such as.:

- Broad Spectrum in action

- Non-toxic for human and birds

- Effective in the presence of moderate amounts of organic material

- Penetrative but not corrosive

- Solubility in Water

- Not associated with foul odour

- Affordable and easily available

- Easy to Use

Many factors influence the effectiveness of disinfectants, such as exposure time, composition and concentration, temperature, pH value, relative humidity and water hardness. Therefore, the choice of disinfectants used and the disinfection time must be carefully considered.

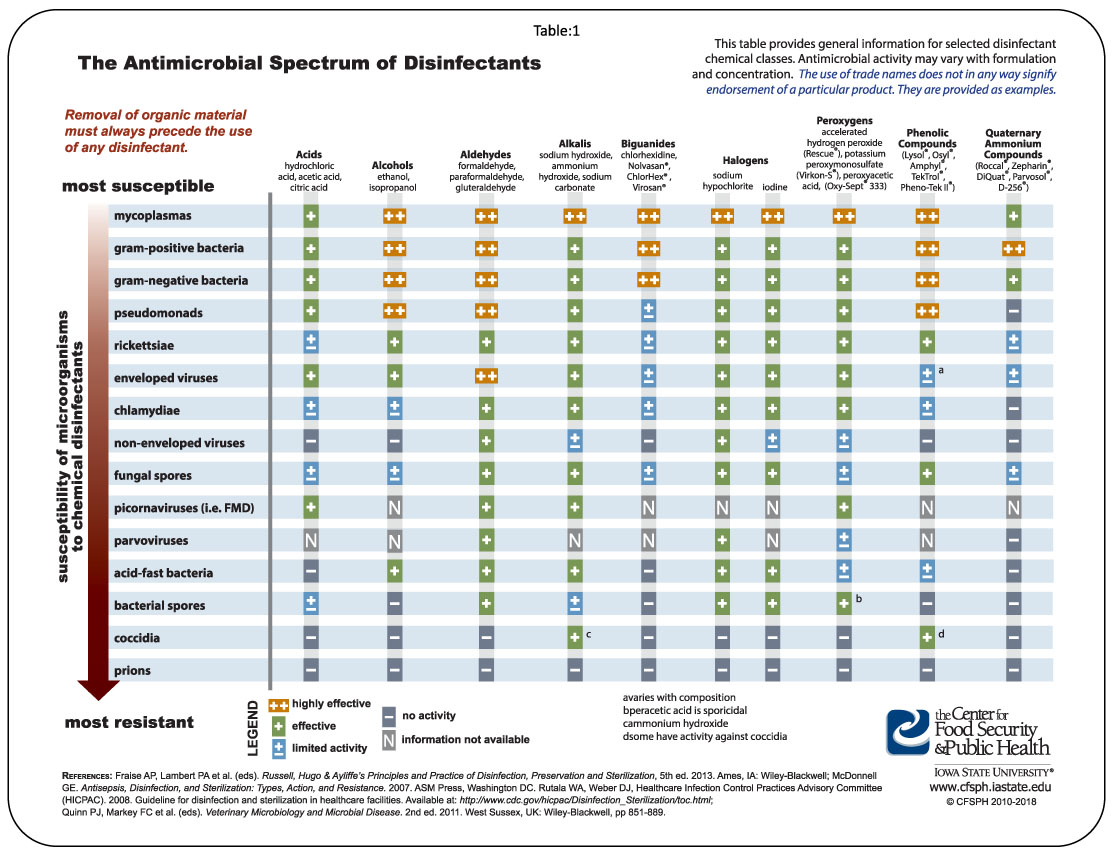

Different types of disinfectants are used to disinfect chicken houses. The comprehensive list is presented in Table 1. To ensure proper disinfection, the following values must be calculated appropriately:

Different types of disinfectants are used to disinfect chicken houses. The comprehensive list is presented in Table 1. To ensure proper disinfection, the following values must be calculated appropriately:

- The area to be disinfected

- The amount of water required

- The amount of disinfectant required

The manufacturer’s directions for mixing and dilution of the disinfectants must be followed. A good rule of thumb is to apply disinfectant solution at the rate of 0.3 to 0.4 litre per square metre of area to be disinfected.

Disinfection is not complete without Testing

Various standards and methods are available to test the effectiveness of disinfectants. Testing is a key factor in confirming that the disinfectants used have achieved the required level of microbial killing on key surfaces.

Effective disinfection is a key biosecurity measure for disease control, and, consequently, an essential component of farm management. The purpose of disinfection is to eliminate pathogens that cause disease. For the objectives to be achieved, it is crucial to understand disinfection principles. Unless the surface to be disinfected is clean, most disinfectants will not work. In addition to their differences in activity against bacteria, viruses, fungi, and protozoa, disinfectants also differ considerably in their ability to kill them.