With the soaring soya price every day, ‘balancing Crude Protein level’ in Poultry feed formulation is a challenge and with soya alternatives is a real task. However, low-cost feed formulation is the need of the hour and inevitable.

We have discussed in this article in detail the “pros & cons” of the “soya alternatives” and their “limitations of usage” in the feed formulation to get the maximum outputs.

We have discussed in this article in detail the “pros & cons” of the “soya alternatives” and their “limitations of usage” in the feed formulation to get the maximum outputs.

Trust this article will be a handy & useful guide to use soya alternatives in the poultry feed formulation.

Soya is Important in Poultry Feed?

Soya is an unbeatable protein source in Poultry feed for the following reasons

- Crude Protein (CP) Average 48% with consistency

- No Contamination & Adulteration

- Rich & Bioavailable Amino Acids source.

Top 5 Soya Producing Countries

Brazil, USA, Argentina, China and India – These 5 countries contribute more than 70% of world’s soya source.

Why Soya Price is Abnormally High & Unpredictable

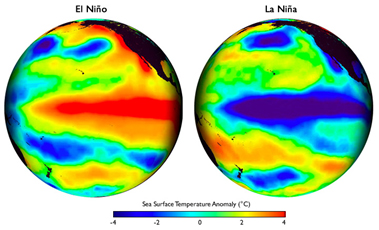

- Global warming effect due to El Niño & La Niña phenomenon caused dry weather to the Soya producing countries like US, Latin America, India, China & Mid West countries and lowered Soya production

- To be topped to the increased demand for Edible oil due to eating habits

- Soya oil has been listed as edible oil & Agri-commodity in the stock exchange.

Challenges in Poultry Feed Cost due to High Priced Soya

Sudden Increase for Soya demand and Advance payment to Soya bean – Blocks Cash Flow rotation in Poultry Industry especially in India.

Soya Inflation rate a serious concern

Soya inflation rate Per Kg Indian Average is 80% vs Grains of 11%

Soya Alternatives

- Soya Alternatives can be of Plant based & meat based.

- However it’s dominated by Plant based protein sources as the nature of the chicken digestive system is made for it with GIZZARD for grinding

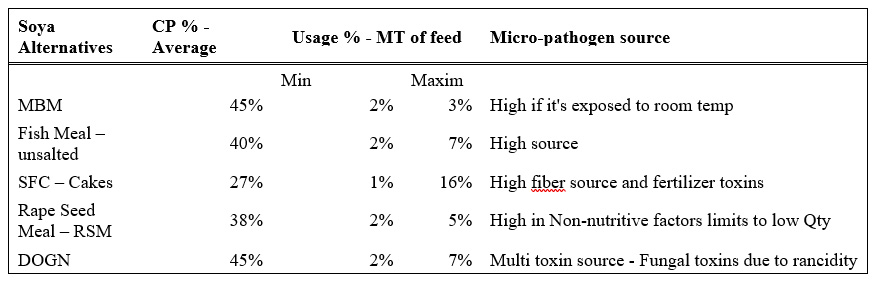

Soya Alternatives – limitations and to be used as combinations

In addition to the above list, DDGs (Dried Distillers Grains), Guar meal, MGM – Maize/Corn Gluten meal and Wheat Gluten meal can be used as per the claims and advise by the consulting vets recommendations as Soya alternatives.

Enzymes – The best Biotech tools

Their usage will be inevitable as high qty of Soya alternatives of Plant based Qty (dominated)

- Xylanase is an important enzyme to accelerate the plant- based soya alternatives in GIT

- Protease is important – can replace Soya as per the Product claims

- NSP/Multi – Enzyme can be used at the recommended dosage by the manufacturers and by the field Vets who are the best judges as they confront the ground realities.

- Phytase to be used to as Calcium & Phosphorus source

Practical ways to get the maximum output from Enzymes

Enzymes should be mixed -grounded with 50 Kg of RSM, DOGN, SFC & MBM.

Later this Enzyme Pre – Mix can be transferred to Main feed

Soya Alternatives & Feed Additives – TWINS & inseparable

Soya alternatives and AGPs & other feed additives are inseparable.

Permitted AGPs, Organic acids, Probiotics, Prebiotics & Toxin binders to be used little more extra than the regular dosage as per the feed formulation ‘given by the consultants (Vets)

- Usage of Approved & Available AGP at the recommended dosage is inevitable in the tropical weather conditions in India, Sri Lanka, Bangladesh, Pakistan and Middle east.

- Toxin binder is must @ more than the recommended dosage/as per consultants’ advice

- Amino Acids (AA) should be 30 to 40% higher than normal to manage the levels Lysine, Methionine & Threonine etc.

Untraditional Feed Formulation – The best reply to High Priced Soya

If we are open minded and untraditional in tuning our Poultry feed formulation with the awareness of facts of Soya Alternatives’ and their own limitations as discussed here, We can easily replace Soya as much as possible which can ease the cash flow rotation of Indian Poultry industry which earns profits only 6 months of the year.

Title Image Credit by jcomp on Freepik

Article by author: Mg Dosage Can Fetch Millions