“Higher the consumption, better is the performance” is a popular saying amongst the poultry fraternity. This popular saying may not be a universal scientific truth but it surely highlights the importance of feed intake (consumption) in the performance of the flock as the amount of feed consumed by poultry is closely associated with the growth performance. Ever growing genetic potential of broilers is further demanding the increase in feed intake by the birds as modern commercial broilers will not grow to their full genetic potential unless they consume their full nutritional requirement each and every day. Simultaneously, it is also now accepted that with higher sustained genetic potential, we now have bird strains that are perhaps more sensitive to any given diet change. Scientific community have equivocally reported that beside adequate diet formulation, maintaining maximum feed intake is the single-most important factor that will determine the rate of growth and efficiency of nutrient utilization in birds.

Business Director

Delst Asia (South Asia)

A slight or ‘transient feed refusal’ is quite common in broilers when the pelleted diet is first introduced in the feeder but recently a rampant increase in the feed refusal incidences have been reported both from poultry farmers as well as the feed milling industry that too from across the different climatic zones and in different time of the year.

To understand this sudden increase in the feed refusal incidences at the farms, it is highly imperative that first we understand the fundamental physiological theories which explains the feed intake control in birds.

Unlike mammals, there is no one theory which explains the control of appetite or feed intake in birds but the most accepted theory explains that a number of signals arrive at the cerebral cortex or hypothalamus and stimulate those nerves that pass through the hypothalamus, from where other nerve networks transmit information to the organs, such as the gizzard, liver, intestine and pancreas. These signals come directly from the food itself (color, shape and smell), whereas others originate from the intestinal tract following the ingestion of food. In contrast to mammals, visual and textural properties of food have a much greater influence on feed intake of birds than taste or smell. The bird will not readily consume feed if it does not recognize it as food by visual means. Birds are also quite sensitive to shape.

Feed Refusal – Dietary or Sensory?

There are several factors which can cause feed intake problems in the broilers and may be broadly categorised as:

- Dietary Factors &

- Sensory Factors

Dietary Factors: Dietary factors that influence feed intake is mainly related to dietary nutrient composition (either deficiency or in excess to the bird’s requirement). Dietary energy has the most predictable effect on feed intake of broilers birds. Feed intake will decrease as dietary energy content increases and will increase as dietary energy content decreases, until it is limited by either gut fill or other physiological limitations. Layer birds manifest better adjustment in their energy consumption as a consequence of dietary energy concentration than the broiler. Dietary protein and amino acid content have more of an indirect effect on feed intake than any direct effect. Similarly, dietary vitamins and minerals, anti-nutritional factors produced by fungal or microbial metabolism in the feed including managemental issues regarding access of feed and water apart from environmental or disease factors also have its effect on feed intake.

Mostly, if the feed refusal is because of dietary factors, this would be common among all flocks rather than one or selected individual flocks.

Sensory Factors: Sensory factors that influence feed intake can be categorized in three basic stages of food ingestion:

-

- Food Recognition;

- Food Prehension & Ingestion; and

- Gastrointestinal Activity.

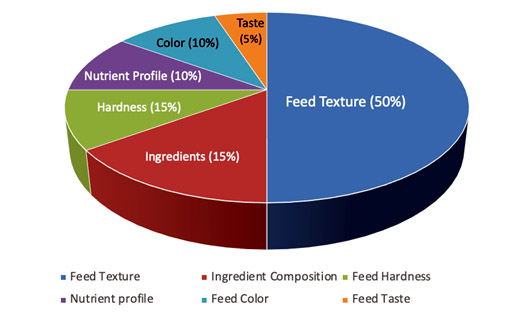

Every time a nutritionist formulates a feed formula with new ingredients, it doesn’t only change the nutrient composition but also the feed pelleting ability during feed processing in the feed mill as well as its final palatability by the birds because of its major change in feed texture. Changes in the physical characteristics of the feed are the main reason behind sensory influences or an alteration in the feed intake. Main physical characteristics of pellets feed texture (dryness & moisture), feed hardness/density, feed colour, feed taste etc.

The physical nature of the feed, namely, the combination of feed texture and hardness, are the overwhelming factors impacting feed intake at the time of diet change, as clearly seen in the transition from crumbs to pellets in young broilers. Changes in ingredient composition and nutrient profile are intimately linked, and together can represent an important additional novel change during this transition. Feed colour and taste are of lesser importance but this maybe because we don’t yet fully understand their significance to the bird.

Recent trends of feed refusal observed in several broiler farms across India have been quite baffling. The pelleted feed from the same batch, supplied to several broiler farms have not only reported farm to farm variation in the feed intake but also some incidences of complete feed refusal. Though it is often difficult to identify the root cause problem of feed refusal unless a complete review of feed and management practices is made but surprisingly sooner the farm switched to a different batch or say new brand of pelleted feed from different manufacturer, the feed intake was immediately resumed. This clearly highlighted the sensory challenges being presented in that particular pelleted diet.

After careful comparative observations between several pellet samples, it was generally noticed that feed texture and pellet hardness were the two most distinguished factors responsible for the rise of feed refusal or scratching incidences at the farms.

Feed texture

Let’s talk and discuss more about the feed texture aspect first. Feed texture is the most important factor which influences the feed consumption in the birds. Mechanoreceptors and chemo-receptors clustered in the birds mouth (taste buds), helps the birds rapidly gauze the feed’s quality by its textural properties. Chickens have an average of about 360 taste buds, out of which approx. 50% located in the palate, around 40% in the floor of mouth, and rest only 4% in the tongue. This taste bud distribution in the buccal cavity of the poultry is directly associated with the contact time of the feed on the different areas of the mouth to enable better gustatory discrimination. Even though poultry have far less number of taste buds than mammals, they do have a good sense of taste and changes in taste. Research papers also concluded that birds are more responsive to weakly flavored foods than strongly flavored foods indicating that a bird’s sense of taste can be overwhelmed.

Also, because of the very high degree of keratinization of the beak, birds have very little ability for oral manipulation of the any kind of feed offered. Feed particles must first be picked up and positioned by the beak and then a forward thrust of the head along with particle release moves the feed to the back of the mouth where it is coated with viscous saliva before swallowing. If the feed is too finely ground and not properly pelleted, it interacts with the saliva and forms a sticky mass that solidifies and interferes with prehension, especially when the diet contains high percentage of broken rice, millets, wheat or other small grains. Researches have confirmed that though mouth cavity of poultry is quite dry, there is a certain role of saliva to first moist and lubricate even the drier feed to push it well down the esophagus.

Though chickens are considered seed-eaters, the efficiency of feed intake is greatly dependent upon the particle size and shape that complements the physical attributes of the bird’s mouth. And this makes uninformed feed milling and feed processing a complete ‘no’ to the feed industry. Birds have clear cut difficulty in consuming pellets that is too large or too small relative to the dimensions of its beak. As poultry do not have teeth, so large particles or pellets cannot be “bitten” and divided into smaller ones. But simultaneously research also suggests that when given a choice, young broilers prefer large particles and generally avoid the smallest particles. Although poultry can apprehend fine feed, they cannot do it efficiently without significant feed wastage. Moreover, they must work more to consume a fine feed than pelleted feed, essentially reducing the productive energy of the feed. If the diet is offered as a meal, consumption will diminish in the young bird when particle sizes are small. If the mean diameter is below 0.8 mm this response becomes clearly noticeable. The depressive effect is proportional to the reduction in mean diameter of the particle. On average each reduction of 100 microns (0.1 mm) is associated with a decrease in intake of 4%. That is the reason why finely ground feeds are poorly consumed by poultry.

Generally the pellets are processed poorly under extreme low moisture and high temperature (with or without high die compression) conditions in tropics, which causes both Maillard Reaction Products (MRPs) as well as Caramelization (a hardened candy effect on the pellet surface) giving the impression of a well formed pellet but a very rough, brittle and a hard pellet surface which poorly affects the feed texture. At the similar die compression and conditioning temperature, the Maillard effect is most profound in all those pellets where moisture lack in penetrating the feed chemistry (particular to starch) which causes the glucosidic link to break away in excessive frictional heat inside the die passage and to react with the lysine. Though not reported, but this could be an interesting future research on Maillard, which involves aldol condensations (an aldehyde-amine condensation reaction) leading to the formation of polymeric compounds called “Melanoidins” (this is what we see in the darkened bread crust) on the surface of pellet and which may be negatively affecting its feed texture and taste.

The presence and proper penetration of water in feed chemistry not only affects the pellet texture but also its structure and uniformity. Even the small amounts of bound water that occurs in feed may have a marked effect on the pellet texture. Feed industry high dependence on PDI (Pellet Durability Index) as only benchmark parameter for pellet quality is certainly now playing a detrimental role to further improve the processed pellet feed quality.

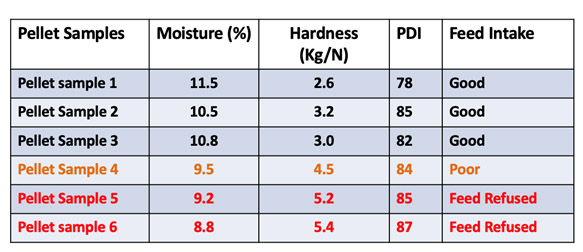

Final moisture available in the pellets have a great significance on determining its texture which make the pellets appear either soft, rough or smooth. Total moisture of the pellets can be defined as bound moisture which is the initial moisture in the ingredients plus added moisture from steam condensation and water added at mixing, if any. In a field survey, we observed that feed pellets with higher than 11.5% total initial moisture had the lowest hardness or feed refusal issues at farms but as the total moisture kept going low below < 10% and up to 8-9%, there was significant increase in pellet hardness along with feed intake issues. Possible explanation of this phenomenon is that relationship between gelatinization and pellet hardness. The feed pellets with higher degree of gelatinization might be softer than the ones with lower degree of gelatinization which is related to the superior distribution of gelatinized starch across the pellets. In general, pellets having adequate moisture content exhibited a texture that is moist, juicy, tender and chewy. But in the pellets where moisture content got lowered, undesirable textural attributes such as dryness, hardness or tightness occurred to the pellet.

Hardness

In a random field study conducted in Northern region of India (Haryana & Punjab), broiler feed pellets (of 3 mm diameter, at average PDI >80) collected from different feed mill factories have shown that broiler farms fed with the pellet hardness range of 2.4 to 3.8 Kg/N and a final moisture range of 10.5 to 11.5% have got significantly higher feed intake than the pellets with hardness range of 4.0 to 5.2 Kg/N and having a moisture range of 8.5 to 10%. Once the hardness of pellets exceeded more than 5 Kg/N and moisture range remained under 10%, complete refusal of pellets was reported from the maximum number of the farms. Hardness of the pellets is defined as the amount of force required to crush the pellet and it can be calculated based on hardness value by dividing the hardness or maximum force to break the pellet (N) by the surface area of the probe (m2). The length of each pellet sample was controlled at the average of 8.5 ± 0.3 mm and diameter at the average of 3.0 ± 0.2mm.

Pellet hardness was analyzed by diametrical compression with Hardness Analyzer (supplied by M/s Insize Co. Ltd.) while the moisture was analyzed with (Portable Moisture Analyser and MX-50 Moisture Analyser).

Pellet hardness was analyzed by diametrical compression with Hardness Analyzer (supplied by M/s Insize Co. Ltd.) while the moisture was analyzed with (Portable Moisture Analyser and MX-50 Moisture Analyser).

Pellet Durability Index (PDI) was determined by putting 500 gm of feed pellets into a tumbling box and spinning at 50 rpm for 10 minutes.

Other Factors

Apart from pellet texture (dryness) and hardness, colour, taste and nutrient/ingredient composition may also contribute to feed refusal but may not be as negatively as these former two sensory factors. A transient change in feed intake or refusal may happen because of ingredient /color or taste in response to feed regime change, but it is clear that the main factor impacting ‘feed refusal’, is feed texture and hardness. For broilers, the most challenging and noticeable period of ‘feed refusal’ is reported at the time when the change from starter crumbs to grower pellets happened.

Graded Response to Feed Refusal

The fear of feed refusal that broilers “wont feed pellets” at an early stage of growth cycle has pushed several poultry growers in the country as well as feed manufacturers in several markets to produce and offer crumbs even much later in the production cycle. There are lots of feed millers who are producing and selling even ‘finisher crumbs’ ignorant to the fact that feeding crumbs will have a bigger impact on reduced growth than accepting any transient feed refusal at an early stage. Not a single research paper has been found which supports feeding of crumbs to finisher birds. But, nutritionist and manufacturers have not only to formulate and process a well nutrient balanced pellets but also a pellet which is easily acceptable and easy to ingest.

The rising incidences of feed refusal and lower feed intake is delaying the introduction of pellets change because of the perception that young birds “will not eat pellets”, this is ensuring reduced feed efficiency. We cannot expect the same feed efficiency of birds fed pellets (vs small crumbs) introduced at 15th day vs as late as 24th day. Research papers also do not support this argument that changing to pellets diet sets the bird back by 2-3 days. Meticulous observations also reveals that for individual birds transient ‘feed refusal’ is observed mainly in the first 20 minutes but that within 24 hours of the diet change, there is compensatory feeding that normalizes, or even exceeds, expected feed intake for that day.

Careful observations have also revealed that the broilers initial reluctance to eat pellets is associated with certain behavioural changes. Birds actually approach the feeder more often at this initial change of feed regime time, but this is often associated with a ‘closed beak’ which supports the observation of birds ‘playing’ with the feed or even scattering feed onto the litter. In the first 20 minutes there are also more instances of birds picking up the pellets but not swallowing them, so again they may be dropped onto the litter. In another report, dropping pellets onto the litter increased 10-fold in the first 20 minutes after initially offering pellets, although actual wastage was just a few gm/bird. However, pellet hardness and colour have been shown to have little impact on this transient ‘feed refusal’ behaviour.

To handle this issue of transient feed refusal at poultry farms which is an inevitable and inherent behaviour, one can add 5% pellets to a crumbed feed 5-7 days ahead of the changeover is one approach that can make sure that birds have access to some pellets prior to the changeover as one approach. Another obvious approach to reduce the adjustment time to any change in feed regime at farms is to feed 50:50 (crumbs: pellets) as the first delivery.

However, when the refusal of feed is prolonged and feed intake doesn’t get normalized within the couple of days at farms, immediate attention should be paid to improve sensory factors like feed texture and hardness along with the total moisture in the pellets.

Conclusion

As with many situations in life, poultry do not like change in any aspect of environment including the diet change. The poultry likes consistency in its environment, including in its diet, and to some extent ingredients used to formulate its diet. However, there is surprisingly little information available on how broilers respond to these abrupt ingredient/diet changes that are necessary as part of modern lifecycle feeding regimes. Once the poultry have become used to one form of presentation of feed, a certain amount of adaptation is necessary if another is provided. And, to help this adaptation, feed millers & processors now have increasingly bigger role to maintain major sensory factors of diets like feed texture (smoothness, dryness, softness) and hardness. Poultry that are fed pellets will need some time to get accustomed before being able to eat the same quantity of feed if the ingredient or diet are to be changed to a meal. Maintaining major sensory factors like feed texture including pellet dryness/hardness will surely reduce this adaptation or shorten the adjustment time for poultry in the farms. Change in the taste and smell of diets are pretty less sensitive to poultry, if compared to mammals as observed in the farms and may not be that important as sensory factors.

About the author:

Dr Naveen Kumar, B.V.Sc & A.H (Gold Medalist), M.V.Sc (IVRI, Bareilly) is a food & oil seed grains storage specialist and a finished feed quality expert for Asian and other tropical countries. He also Business Director of Delst Asia and is located in Faridabad, India. He can be reached at naveensharma21@gmail.com, Mobile +91 93502 89123.

Title Image Source: FreePik

Article by same Author: Pellets: “High Fines” Might Exaggerate Diseases At Poultry Farms