With rising raw material costs and never ending disease problems, the future landscape for doing this business profitably will be dauntingly more challenging. Rising feed additives costs, and inconsistent feed ingredient quality add more difficulties and uncertainties to the sustainability of poultry farming.

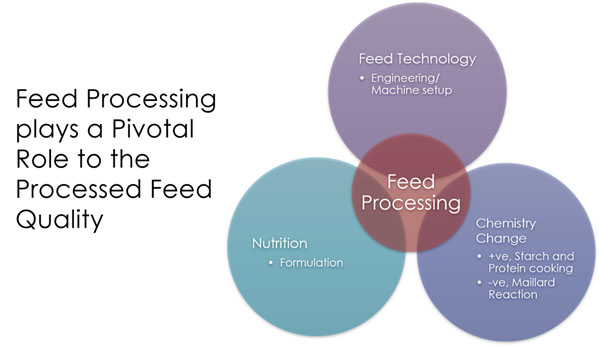

Let’s face this fact and ask the golden question “What more can be done to improve farm productivity and profitability?”. We cannot control rising ingredient costs, so the only thing left is to look inwardly for a better understanding of feed processing and the economic benefits of improving processed feed quality.

Let’s face this fact and ask the golden question “What more can be done to improve farm productivity and profitability?”. We cannot control rising ingredient costs, so the only thing left is to look inwardly for a better understanding of feed processing and the economic benefits of improving processed feed quality.

This article addresses an area of feed processing which many in the industry are most likely not aware of, due largely to the generally well accepted norm in feed processing and assessment of feed quality.

Feed Imaging exposes problems that could well explain the issues with high feed costs, poor farm productivity, and low survival rate. This forensic science also provides a much better post-mortem insights into the quality of processed poultry feed over current analysis – wet chemistry analysis for starch gelatinisation, PDI and Maillard Reaction.

Feed Imaging shows up accurate visual macro details for assessing the processed feed quality:

1) Poor Processing of Starch/Protein – This affects pellet binding, energy value and feed intake. The feed pellet could be very stable, but if intra-particles bonding is poor in the entire pellet, fines and dust can easily fall off while the pellets are being handled. Also feed intake in farm is directly related to texture of the pellets, 50% of pellet rejection incidences at farms are related to the texture of the pellets. Poorly processed starch and protein directly affects pellets texture and its intake at farms which will certainly affect the farm performance.

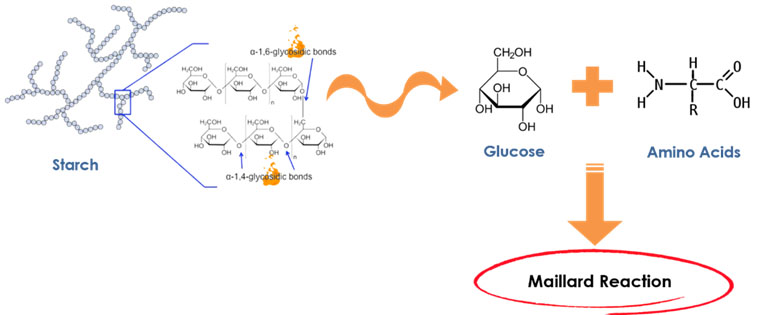

2) Maillard Reaction – Reaction of lysine/ and some other amino acids with reducing sugars such as glucose. This reaction impacts protein quality, critical for poultry nutrition. Certainly, we know that Maillard reaction binds lysine, making it non-reactive, and interferes with the transport of stored nutrients to the muscle for growth.

Maillard compounds have many negative effects on the poultry health as well as effects on absorption and storage of nutrients, synthesis and secretion of several enzymes for food digestion.

No More Guessing and Assuming that everything is fine!

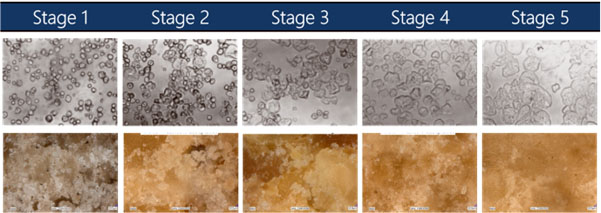

• Changes in morphology of maize starch granules throughout the gelatinisation range, showing birefringence when observed under digital light microscopy

• As starch starts to gelatinise with sufficient moisture and heat, we start to observe an increase in granule size, loss of integrity, granular disruption and the eventual loss of birefringence.

• Finally, with the microscope image showing up the glass transition surface

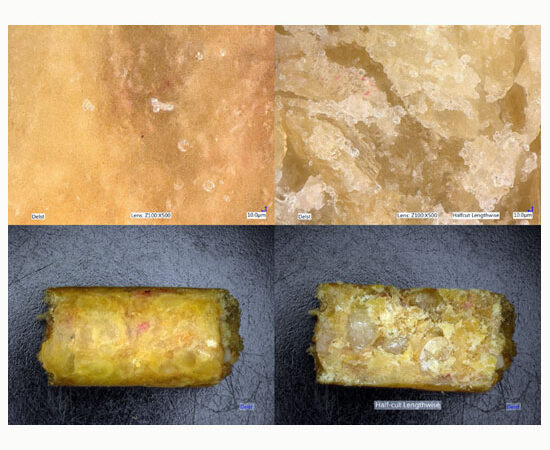

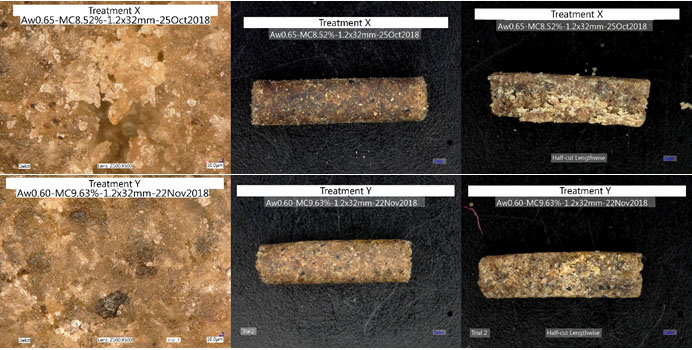

What this image of a typical feed is telling us?

1) Starch poorly processed – Clear birefringence, moisture not penetrating the starch granules

2) A high degree of visible crystalline starch – Whitish streaks clearly indicating a lack of moisture hydrating the starch granules. When sufficient moisture penetrates the granule, the amorphous regions of the granules absorb the moisture and swell, resulting in the separation of starch chain from the crystallites. Sufficient water lowers the starch melting point and result in quick melting of the crystallites at high temperature.

3) Darkened colour – Clearly indicating browning from Maillard reaction. Sufficient moisture prevents the breakage of glucosidic-bonds holding glucose to carbohydrates. The Maillard reaction occurs when breakaway free glucose reacts with lysine.

What is the problem with the current pelleting process?

Feed pelleting is a complex, semi-dry thermal processing, rendering it impossible to deal with the objective of processing starch and protein well, without the dreaded Maillard reaction problem.

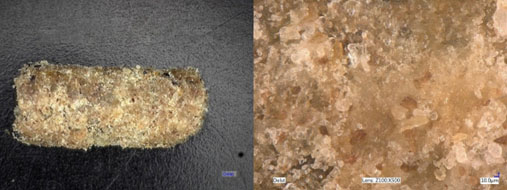

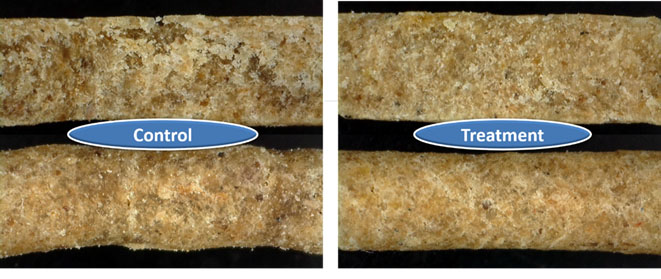

The industry has been working under the notion that the feed has been processed well enough, but feed imaging now shows up the problems clearly. Feed pelleting is merely a forced feeding of hot-moist conditioned mash through the die, and at best, only the pellet surface is anywhere close to being better cooked due to high surface moisture and searing effect from the hot die surface. Hence, Pellet Durability Index (PDI) is merely a measure of the strength of the outside of the tube (integrity of the pellet surface). Putting a knife through a pellet often reveals a brittle exterior and very loosely bonded centre, as shown by feed imaging. This is the reason PDI improves when there is more surface moisture in the hot mash and with the higher die compression used for pellet production.

We are seeing abnormally high issues with the starch in the processed pellets. The whitish streaks and rough pellet surface are good indicators that things are not quite right. These weaknesses are clearly observed on all feed put under the microscope. Some obvious factors such as low moisture at conditioner, high temperature processing and high die compression make things worse.

In a very different context away from current industry norm, the main objective with feed processing should be:

- Induce positive chemistry changes to starch and protein

- Minimise the negative chemistry changes caused by Maillard reaction.

Using these fundamental principles, the next steps are to deploy the sciences needed to get the job done correctly and optimally.

Moisture plays a very important role in feed processing. It is one of 3 elements involved in cooking food – Heat, Moisture, Time. An effective moisture management technology determines if moisture will be used “functionally”, which greatly determines production efficiency and the processed pellet feed quality. Moisture can only be functional if it is being drawn into the feed chemistry…. Contributing to positive chemistry changes to starch and protein.

Mash Hydrolysation TM

The whole Science around feed pelleting is centered around the proper hydrolysis and cooking of starch and protein. For this to happen, moisture need to get into the feed chemistry. However, the polarity of water molecule alone is insufficient to disrupt the hydrogen bonding of starch and protein structures.

A group of chemicals which contain divalent cations termed as “structure breakers” with a high charge density having the ability to disrupt hydrogen bonds of starch and protein. These cations also possess high polarity, thus attract water molecules strongly. With the disruption of hydrogen bonds, moisture can penetrate freely into the starch granule, leading to swelling, rupture, and the melting of amorphous and crystalline starch ……leading to starch gelatinisation irreversibly. Such bio-chemistry solution is important for activating moisture into the feed chemistry in the semi-dry feed pelleting process.

In the current low moisture scenario, when water molecules do not easily penetrate into the starch granules and can’t stay retained in the feed chemistry even after higher moisture addition in the mixer, Feed Imaging can easily work as a torch bearer to help feed millers gauge their pellet quality and to know how good they are able to use this added moisture to improve the feeding value of pellets.

Authors: Steven Goh and Dr Naveen Kumar, Delst Asia

For more details, write to drnaveen@delstasia.com

Previous article by author: Understanding Recent Feed Refusal And Poor Feed Intake